What is Lead

Certifications

of Epoch Analytical Inc.

EPOCH is accredited with the US National Voluntary Laboratory Accreditation Program (NVLAP) for bulk asbestos sample analysis under NVLAP Code 200746-0

EPOCH is accredited with the Canadian Association for Laboratory Accreditation Inc. (CALA) for airborne fiber analysis (Membership No. 3533).

1. What is lead?

1. What is lead?

Lead is a naturally occurring metal found in rock and soil and also has many industrial applications. Due to both its natural occurrence and long history of global use, lead is ubiquitous in the environment and is present in air, water and soil as well as in food, drinking water and household dust. Lead is a highly toxic material that can cause severe neurological disorders and cancer. Lead is often found in the renovation, demolition, manufacturing, and recycling industries. One of the best ways to protect workers against lead exposure is to practise good hygiene at work.

2. What are the health effects of lead?

2. What are the health effects of lead?

Because the early symptoms of lead poisoning are easy to confuse with other illnesses, it is difficult to diagnose lead poisoning without medical testing. Early symptoms may include persistent tiredness, irritability, loss of appetite, stomach discomfort, reduced attention span, insomnia, and constipation. Failure to treat children in the early stages can cause long-term or permanent health damage. The current blood lead level which defines lead poisoning is 10 micrograms of lead per deciliter of blood.

3. Where is lead located?

3. Where is lead located?

Older homes may contain lead based paint.

Lead was used as a pigment and drying agent in “alkyd” oil based paint. “Latex” water based paints generally have not contained lead. About two-thirds of the homes built before 1940 and one-half of the homes built from 1940 to 1960 contain heavily-leaded paint. Some homes built after 1960 also contain heavily-leaded paint. It may be on any interior or exterior surface, particularly on woodwork, doors, and windows. In 1978, the U.S. Consumer Product Safety Commission lowered the legal maximum lead content in most kinds of paint to 0.06% (a trace amount). Consider having the paint in homes constructed before the 1980s tested for lead before renovating or if the paint or underlying surface is deteriorating.

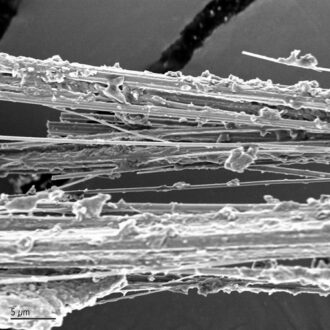

Enlarged Asbestos Fibers

4. How can I find out more about lead?

4. How can I find out more about lead?

5. How do I submit a sample to test for lead content?

5. How do I submit a sample to test for lead content?

Paint chips can be collected and submitted to a laboratory for lead analysis. The US National Institute of Occupational Safety and Health (NIOSH) has developed a number of methods for analyzing lead in paint, including Methods 7082, 7105 and 7300. The paint sample collected should be about about 2.5 centimeter (cm) by 2.5 cm in surface area. When collecting paint samples, you must make sure that all of the layers of paint or coating are collected, right down to the original surface. If you cannot remove the paint from the substrate, you can submit the sample with it attached.

6. What amount of lead is considered safe?

6. What amount of lead is considered safe?

In 1976, federal government regulations limited the amount of lead in interior paint to 0.5% by weight. Exterior paints can contain more than 0.5% lead by weight, but paint cans have to be labeled with a warning that the paint contains lead and is not to be used on surfaces children can chew.

By 1991, Canadian paint manufacturers had voluntarily stopped using lead altogether. Paint in your home that is more than a few decades old may contain lead. Lead levels vary depending on when the paint was manufactured.

If your house was built between 1960 and 1980, the interior or exterior paint may contain small amounts of lead. If it was built before 1960, and surfaces are covered with several layers of paint, your house undoubtedly contains high levels of lead.

Besides paint, many types of ceramic tiles used in residential and commercial buildings from 2000 and newer imported from overseas and manufactured in foreign countries contain high concentrations of lead in their glaze.

WorkSafeBC does not numerically define what would be considered a lead containing or a lead based paint or coating. However, Health Canada defines a lead containing surface coating or paint as over 90 PPM, which is also known as 90 mg/kg, or 0.009% dry weight of lead. You should be aware that any amount of lead in a material may pose an exposure risk to workers when the material is disturbed, depending on the method. A risk assessment should include the presence of high risk individuals, especially pregnant women and children, within the workplace.

7. How do I submit a sample to test for lead content?

7. How do I submit a sample to test for lead content?

paint chips can be collected and submitted to a laboratory for lead analysis. The US National Institute of Occupational Safety and Health (NIOSH) has developed a number of methods for analyzing lead paint, including methods 7082, 7105 and 7300. The paint sample collected should be no smaller than about 2.5 x 2.5 cm in surface area. When collecting lead paint samples, make sure that all layers of paint are collected right down to the original substrate. If you cannot remove the paint from the substrate (i.e. wood, concrete, plaster, drywall) you can submit the sample with it attached.

A minimum 100 grams of paint and substrate should be submitted for Toxicity Characteristic Leachate Procedure. TCLP is a test method used to determine the mobility or leachability of lead in liquid and solid waste for purposes of disposal. It is conducted after lead content is determined by one of the many laboratory test methods or X-ray fluorescence analysis. Results are reported in mg/L.

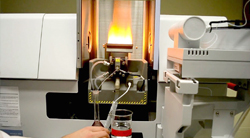

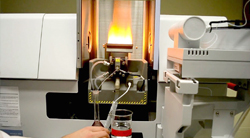

Lead (Pb) Detection by Flame Atomic Absorption Spectroscopy (FAA) NISOH 7082

Epoch Analytical is pleased to now offer lead analysis of paints and coatings using a Flame Atomic Absorption Spectrometer. FAA analyzes lead content according to modified EPA 7000B and test method NIOSH 7082.

Using Flame AA Spectroscopy, a small quantity of sample is homogenized and microwave digested using nitric acid. The lead concentration sample is accurately determined in PPM (parts per million) using the reading from the Flame AA spectrometer following microwave digestion and dilution of a small quantity of the original sample. Please submit a sample that is no smaller than 2″x 2″ size or a minimum 100 grams in weight.

The technique is based on the principle that ground state metals absorb light at a specific wavelength. Metal ions in a solution are converted to atomic state by means of a flame. The main advantages of Flame AA include the output of highly reliable analytical results while maintaining a fast turnaround time.

To quantitatively determine the lead (Pb) content in paint and coatings, NIOSH 7082 is used. Paints chips are decomposed using mineral acids, and prepare appropriate dilutions. and measure these paint samples by aspirating them into an air-acetylene flame for atomic absorption measurement using NIOSH 7082.

Flame analysis is suitable for most analytes and matrices including paint, wipes, soils and air samples and results are reported in PPM or %. For ceramic tiles, the glazing or surface coating of the tile is analyzed for lead content using XRF Analysis.

The Limit of Detection (LOD): approx. 40 ppm or 40 mg/kg based on a 0.25g sample weight. Please submit a sample that is no smaller than 2″x 2″ in size or minimum 100 grams in weight.

Bulk Sample Asbestos Identification using EPA600/R93/116

Bulk Sample Asbestos Identification using EPA600/R93/116

Blown Insulation

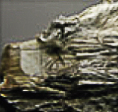

Brick Mortar

Ceiling-Tile

Drywall Joint Compound

Linoleum or Vinylsheet

Paper Tape

Plaster

Exterior Stucco

Texture Coat

Vermiculite & Blown Insulation

Window Putty

Vinyl Floor Tile

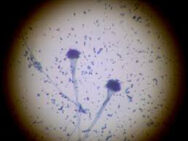

Bulk Asbestos Identification using Polarized Light Microscopy (PLM) in accordance to EPA/600/R-93/116 and EPA600/M4-82-020.

Examination of samples for asbestos content was conducted in accordance to EPA/600/R-93/116 or EPA/600/M4-82-020 methodologies using polarized light microscopy (PLM). This method is the most widely used method for estimating asbestos in bulk building materials and works well for most sample types.

Multiple layers of samples are analyzed and reported separately. All analysts are derived from calibrated visual estimate and measured in weight percent unless otherwise noted. Please note that the EPA test method has limitation for quantifying the percentage of samples with low asbestos concentration.

Transmission electron microscopy (TEM) would be encouraged for customers to obtain accurate results in these situations.

Using Stereoscopic Evaluation

All samples are analyzed first through stereo binocular examination. By magnifying a bulk sample at up to 40x, the analyst is able to evaluate and extract suspicious fibres that possess the morphological characteristics of asbestos. From there, fibres are mounted on a slide with a refractive index oil and then analyzed with the Polarized Light Microscope (PLM).

Using Polarized Light Microscopy (PLM)

Polarized light microscopy (PLM) analysis is the most commonly accepted technique for analysing bulk samples for asbestos. Identification of asbestos is based on the determination of optical properties displayed when the sample is treated with various dispersion staining liquids. Identification is further substantiated by fibre morphology and the effect of polarized light on the fibres. PLM analysis is specific to fibrous materials and allows for the determination of:

There are 6 types of Asbestos

Chrysotile

Amosite

Crocidolite

Tremolite

Anthophyllite

Actinolite

Asbestos Type: There are six (6) types (Chrysotile, Amosite, Actinolite, Tremolite, Crocidolite Anthophylite);

Quantification: % amount of asbestos and non-asbestos fibers in the sample quantified by Calibrated Visual Estimate of the analyst;

Fiber Colour under microscopic evaluation;

None Detected : Means No Asbestos Present in sample

Airborne Asbestos Fiber Counting using Phase Contrast Microscopy (PCM) in accordance to NIOSH 7400

Airborne Asbestos Fiber Counting using Phase Contrast Microscopy (PCM) in accordance to NIOSH 7400

In testing for asbestos, air is drawn through a filter. This filter is usually a part of a 25-mm cassette that can take specific sampling times. The sampling time is chosen to produce a fiber density of between 100 to 1,300 fibers/mm2; this rate is usually 0.5 to 16.0 liters/minute. The filter is then analyzed by phase contrast microscopy (PCM) or transmission electron microscopy (TEM). Fibre counting analysis is conducted in accordance to The National Institute for Occupational Safety and Health (NIOSH) Method #7400.

Enlarged Asbestos Fibers

The National Institute of Occupational Safety and Health (NIOSH) method 7400

The analysis includes testing of air sample for asbestos and other fibers by PCM. It is used primarily for estimating asbestos concentrations in air. The method does not differentiate between asbestos and other fibers and can also be used to estimate the airborne concentration of other, non-asbestos materials such as fibrous glass. Fibre less than 0.25 microns in diameter will not be detected with this method.

The National Institute of Occupational Safety and Health (NIOSH) method 7402

NIOSH 7402 is fibre specific and can be utilized to complement the phase contrast microscopy method 7400. It can determine the fraction of asbestos fibres among all optically visible fibres within a given sample. The results can be used to calculate a modified PCM fibre count.

PCM works well for testing airborne fibers because it is relatively inexpensive and quick. However, PCM does not differentiate between asbestos and other fibers. All fibers that meet the counting criteria are counted. Transmission Electron Microscopy (TEM) is encouraged for customers to obtain more accurate results where precise determination of airborne asbestos fiber is needed.

Gravimetric 400 and 1000 Point Count for Bulk Asbestos

Gravimetric 400 and 1000 Point Count for Bulk Asbestos

Gravimetric point counting is a technique that enhances quantification of asbestos in bulk building materials.The sample is first dried and then weighed. It is then subjected to high temperature in an ashing furnace for a period of approximately 6 hours. During this process organic material is oxidized (burned). After cooling the sample is re-weighed and the weight loss recorded.

Further treatment with dilute hydrochloric acid may be used to remove carbonates and other acid soluble substances in the sample. The remaining material is then washed with plain water, dried and weighed. This weight loss is also recorded. The residue is now examined and PLM point counting is performed to determine the concentration of asbestos fibers in the residue. Because we know the weight of the residue we can calculate the concentration of asbestos in the original sample.

Gravimetric point count improves the ability to detect asbestos fibers in the sample and also improves the quantification. This is so because the residue is very often granular particulates rather than a wide variety of materials with vastly different density and mass thereby making more representative slides and improving point counting statistics.

Point counting does not apply to the EPA vermiculite method.

The Asbestos 400 Point Count reporting limit is <0.25% and Asbestos 1000 Point Count reporting limit is <0.1%.

Vermiculite Research Method by PLM using EPA600/ R-04/004

Vermiculite Research Method by PLM using EPA600/ R-04/004

Vermiculite is a mineral which was commonly used as insulation in buildings, amongst other commercial and consumer products. While not all vermiculite may contain asbestos fibers, it is reasonable to assume that older vermiculite insulation should be analyzed by an accredited asbestos laboratory. WorkSafeBC recommends that the Vermiculite Research Method, EPA/600/R04-004, otherwise known as the “Cincinnati Method”, be utilized. Regular analysis by Polarized Light Microscopy (PLM) using EPA/600/R93/116 may not be adequate to detect asbestos amphiboles from an insufficient sample size to determine the presence or absence of asbestos, the Cincinnati Method is more precise and accurate due to a two-step extraction process using water to separate the amphibole asbestos fibers.

If NO asbestos amphiboles are detected in the fractions, Transmission Electron Microscope (TEM) is the final step of analysis to confirm the presence or absence of asbestos. Any % amount of asbestos detected in vermiculite, is considered an Asbestos Containing Materials (ACM) according to WorkSafeBC. Please submit at least 4 gallons or a full 6″x7″ zip lock large freezer bag of vermiculite for analysis – an insufficient quantity of vermiculite may be rejected and will delay analysis.

Lead Detection in Paints and Coatings

Lead Detection in Paints and Coatings

Until the 1980s, lead was used in paint because of its increased durability, ability to make colours more vibrant, and help paint dry faster. Lead-containing paints and coatings do not present a hazard if they are left intact. The health risk occurs when the paint chips, peels or is otherwise damaged and lead dust, mist or fumes are released into the work environment. Inhalation and ingestion of lead in the smallest of quantities, particularly by children, can be deadly.

Please be aware WorkSafeBC does not numerically define what would be considered a Lead containing or lead based paint or coating. The lead content of paint must be determined as part of the risk assessment by a qualified professional. Please submit a sample that is no smaller than 3″x 3″ in size in a zip lock bag. coatings” For ceramic tiles, the glazing or surface coating of the tile is analyzed for lead content.

Please be aware WorkSafeBC does not numerically define what would be considered a lead containing or a lead based paint or coating. Any amount of lead in a material may pose an exposure risk to workers when the material is disturbed, depending on the method. Any risk assessment should include the presence of high risk individuals, especially pregnant women and children, within the workplace.

For more information about lead exposure and recommendations on providing suitable safe work procedures, please refer to the WorkSafeBC publication, Safe Work Practises for Handling Lead (2017).

At Epoch Analytical Inc we can test lead content in Paints and Coatings using two different methods.

Lead (Pb) Detection by Open Beam X-Ray Fluorescence (XRF) Analysis

Lead (Pb) Detection by Open Beam X-Ray Fluorescence (XRF) Analysis

EPOCH uses Open Beam X-Ray Fluorescence (XRF) technology to conduct our lead testing methods as a fast (immediate), non-destructive technique of testing for lead in surface paints and coatings. The XRF analyzer measures the amount of lead in paint and other surface coating by exposing a painted or coated surface to X-rays or gamma radiation, which then causes any lead present to emit energy with a certain frequency.

The results from XRF analysis can be reported in either volume as ppm (parts per million) or surface area as mg/cm2. Please submit a bulk sample of paint that is at least 2-3 inches in surface area. Lead surface wipes can also be analyzed by XRF. Please be sure to

The limit of detection (LOD) using XRF for volume is approximately < 20 ppm or mg/kg.

Our technicians are certified XRF analyzer operators and have acquired a Level 1 X-ray Fluorescence Analyzer Operator Certificate issued by the Natural Resources Canada (NRCan).

Lead (Pb) Detection by Flame Atomic Absorption Spectroscopy (FAA) NISOH 7082

Lead (Pb) Detection by Flame Atomic Absorption Spectroscopy (FAA) NISOH 7082

Epoch Analytical is pleased to now offer lead analysis of paints and coatings using a Flame Atomic Absorption Spectrometer. FAA analyzes lead content according to modified EPA 7000B and test method NIOSH 7082.

Using Flame AA Spectroscopy, a small quantity of sample is homogenized and microwave digested using nitric acid. The lead concentration sample is accurately determined in PPM (parts per million) using the reading from the Flame AA spectrometer following microwave digestion and dilution of a small quantity of the original sample. Please submit a sample that is no smaller than 2″x 2″ size or a minimum 100 grams in weight.

The technique is based on the principle that ground state metals absorb light at a specific wavelength. Metal ions in a solution are converted to atomic state by means of a flame. The main advantages of Flame AA include the output of highly reliable analytical results while maintaining a fast turnaround time.

To quantitatively determine the lead (Pb) content in paint and coatings, NIOSH 7082 is used. Paints chips are decomposed using mineral acids, and prepare appropriate dilutions. and measure these paint samples by aspirating them into an air-acetylene flame for atomic absorption measurement using NIOSH 7082.

Flame analysis is suitable for most analytes and matrices including paint, wipes, soils and air samples and results are reported in PPM or %. For ceramic tiles, the glazing or surface coating of the tile is analyzed for lead content using XRF Analysis.

The Limit of Detection (LOD): approx. 40 ppm or 40 mg/kg based on a 0.25g sample weight. Please submit a sample that is no smaller than 2″x 2″ in size or minimum 100 grams in weight.

Mold and Bacteria Analysis

Mold and Bacteria Analysis

Accurate identification of molds is important. It helps alleviate unnecessary concern and aids in decision-making.

Suitable samples for mold testing include:

• Pieces of material with signs of mold.

• Tape lift or swab samples taken from surfaces suspected of mold.

• Air samples: These include non-viable and viable samples.

Mold testing involves analysis of samples collected from residential and commercial properties. Samples for mold testing include air for either viable or non-viable analysis and surface samples such as swabs, bulk (pieces of material, dust or liquids), tape lift, and contact plates.

Direct Microscopic Examination (DME) is using x400, x600, or x1000 magnification as necessary.

Culture and quantification is also available. Mold and Bacteria Analysis is conducted by trained microbiologists from an accredited laboratory.

Transmission Electron Microscopy (TEM)

Transmission Electron Microscopy (TEM)

What you can see with a light microscope is limited by the wavelength of light. TEM uses electrons as a “light source” and their much lower wave length makes it possible to get a resolution at A higher magnification (up to 20,000x and higher) and identifies asbestos fibers by morphology, crystalline structure and elemental analysis.

As there are no TEM laboratories in western Canada, Epoch Analytical will facilitate and coordinate the sending of samples to an accredited laboratory for TEM analysis.